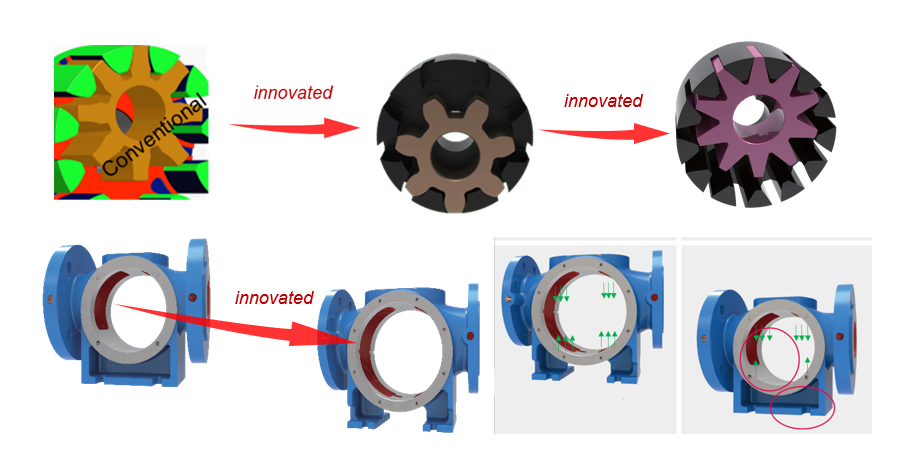

The internal gear pump was invented more than 100 years ago, but at that time the invention has significant drawbacks: lower efficiency, larger noise and vibration due to low gears engagement ration.

With SMC technical innovations for pump rotor profile and pressure balance casing, SMC gear pump advantages achieved:

1.efficiency increased 10%

2.noise reduced 10%

3.vibration reduced 0.8 mm/s

4.rotors engagement ratio up to 1.4

5.motor speed gear pump available

6.gear pump pressure is up to 40 bar