Low viscosity fluid and high-pressure operation is generally a challenge for screw pump, because internal fluid leakage between rotors and liner leads to low efficiency or even failure of required outlet pressure. The key to resolve this problem is to optimize rotor profile and improve parts machining accuracy, also select correct material.

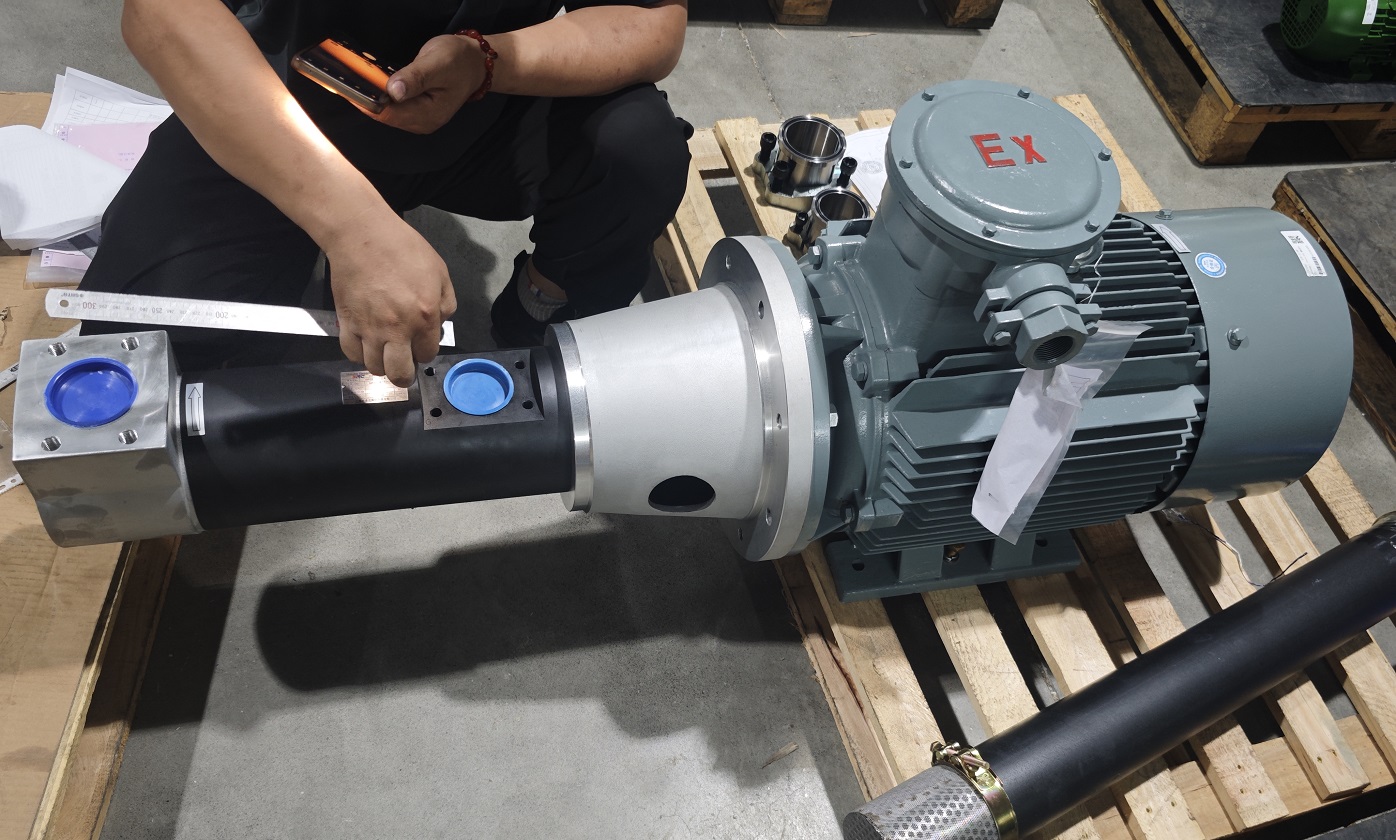

With rich nickel content globally, Indonesia customer PT CERIA uses advanced rectangular rotary kiln electric furnace to produce 63200 tons of ferronickel per year. They use SMC screw pump to transfer 35 bar low viscosity diesel oil during nickel alloy smelting process. Compared with centrifugal pump, screw pump can generate stable discharge pressure even there is flow change. PT CERIA purchased two more SMC screw pumps in 2025 July after 1st purchasing in the year of 2023.The GR series three screw pump features simple structure and low noise for clean oil transfer and loading.