General introduction

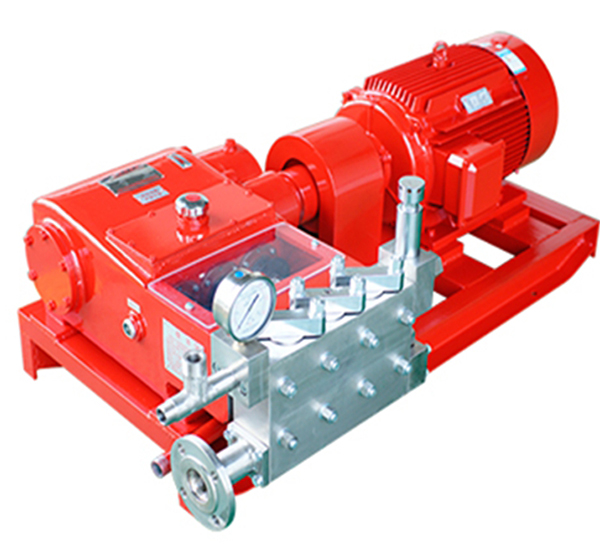

Reciprocating plunger pump is a kind of positive displacement pump, that converts the mechanical energy into hydraulic energy by sucking the liquid into a cylinder. In this pump, a plunge is reciprocating, which uses thrust on the fluid and increases its hydraulic energy. It is often used where a small quantity of fluid handled and where delivery pressure is quite large.

Normally there are three-plunger/piston pump and five-plunger/piston pump.

Key features

1. three or five cylinders available

2. API 674 standard compliance

For details, contact sales@shenmech.com

Performance range

- Pressure: Max.180 MPa

- Capacity: 118 m3/h

- Temperature: up to 400 ℃

- Plunger stroke: 818 mm

General introduction

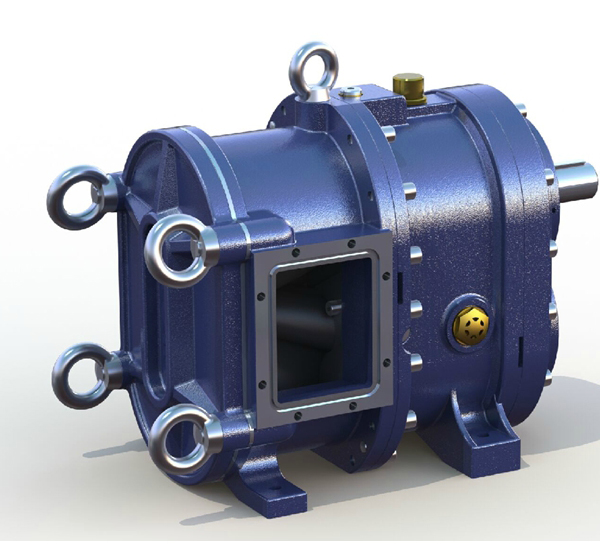

Rotary lobe pump is a kind of positive displacement pump, the two or three rotary lobes installed on shafts are driven through timing gears, during operation the sealed chambers are formed between casing and rotors, fluid is suctioned from pump inlet and discharged to pump outlet almost without any shear force or pulsation, it is especially applicable for pumping fluids with certain sludges or suspensions, also big capacity compared to progressive cavity pump.

Sanitary lobe pump with stainless steel wetted parts is applicable for food industry.

Key Features

1.Due to symmetrical structure, shaft rotation direction is reversible

2.Easy installation and maintenance (Maintenance in Place = MIP)

3.Good self-priming ability compared to centrifugal pump

4. Max.50 mm diameter particle is allowed for pumped liquid

5. Low shearing force to pumped liquid

6.Various installation modes

Performance Range

-Capacity: 5 – 1428 m3/h

-Pressure: Max.11 bar

-Speed: 150-500 rpm

-Viscosity: up to 100000 cp

-Temperature: up to 113 ℃

For catalogue, contact sales@shenmech.com

General introduction

The slip-fit vanes of pump are placed in the slotted rotor, and the rotor is eccentrically installed in the pump casing. When the rotor is rotated by driver, the sliding vanes slide out of the rotor and close to the internal surface of the pump casing. The cavity chamber formed by the rotor, sliding vanes and pump casing changes periodically with the rotation of the rotor. When the cavity chamber is enlarged, the medium is suctioned and discharged when the cavity becomes smaller. The transmission process of the medium is completed again and again.

Key features

1.Good self-priming ability (up to 5m within 20 second)

2.Liquid-gas phases applicable pumping (gas Max.48%)

3.Dry run allowable up to Max 8 min

4.Slip-fit vanes to ensure pump performance against wears

5.Easy maintenance (simple vanes change procedure)

6.Applicable for volatile organic fluids as non-metal with non-metal contacts

Performance Range

-Capacity:3-200m3/h

-Pressure: Max.10bar

-Temperature: -35 to 75 ℃

For catalogue, contact sales@shenmech.com