General introduction

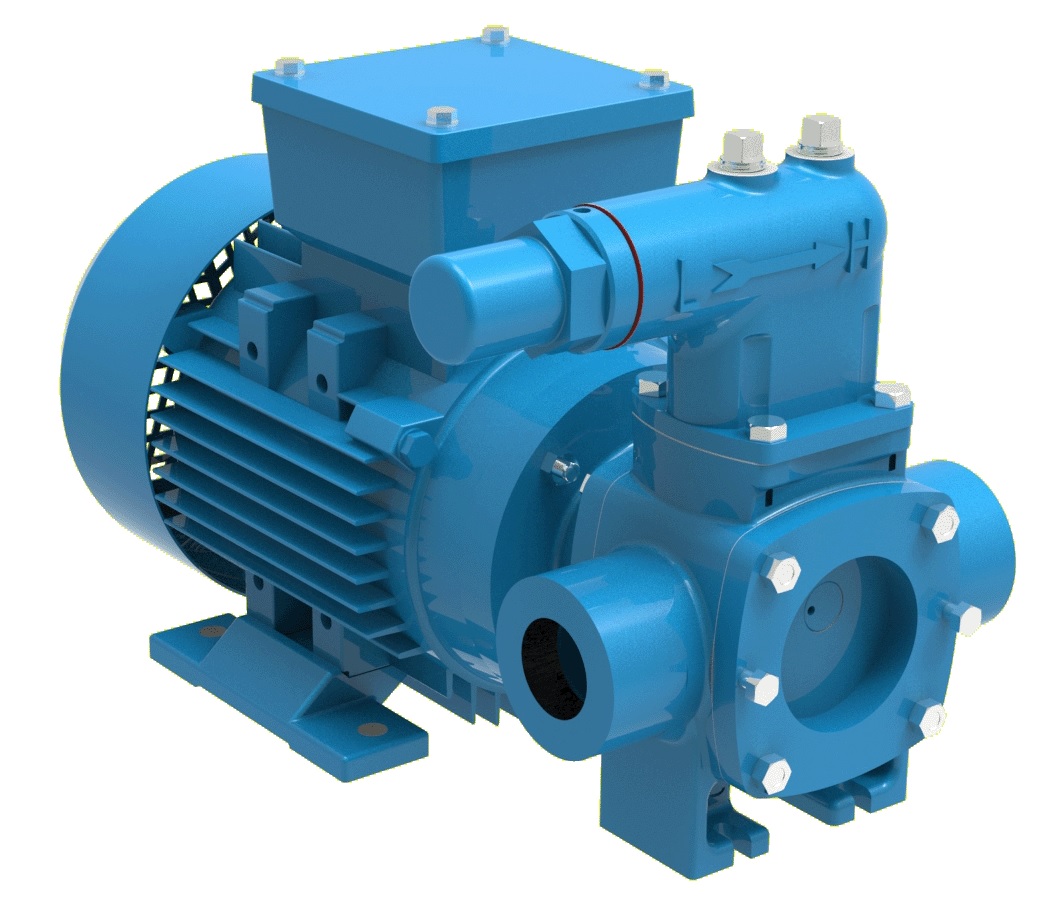

When the gears installed on shaft rotate, the suction chamber volume is increased to suck fluid, and discharge chamber volume is decreased to deliver fluid with casing, meshing gears and covers. It is typically used for viscosity fluid pumping such as clean fuel oil, lube oil, resin, bitumen, paint, or edible oil. Achieved best efficiency in China for internal gear pump due to technology innovation and patents.Normally,gear pump includes internal gear pump and external gear pump, our internal gear pump series as below:

NL series:Heavy duty multi-function NM series:General purpose

NE series:Magnetic drive leak-free NC series:Close-coupled

Key features

1.Easy to use and maintenance

2.Simple structure with shaft, gear, cover, casing, bearing

3.Steady fluid flow comparable to diaphragm pump

4.Cannot dry run, cannot handle fluid with solid or abrasive

5.Internal gear pump is applicable for higher viscosity liquid

6.Horizontal or vertical installation

7.Heating jacked casing or magnetic drive available

Performance range

-Capacity:410 m3/h

-Pressure: Max.18 bar

-Temperature: 280℃

-Viscosity: 300000 cSt

For Russian sales, contact our local distributor

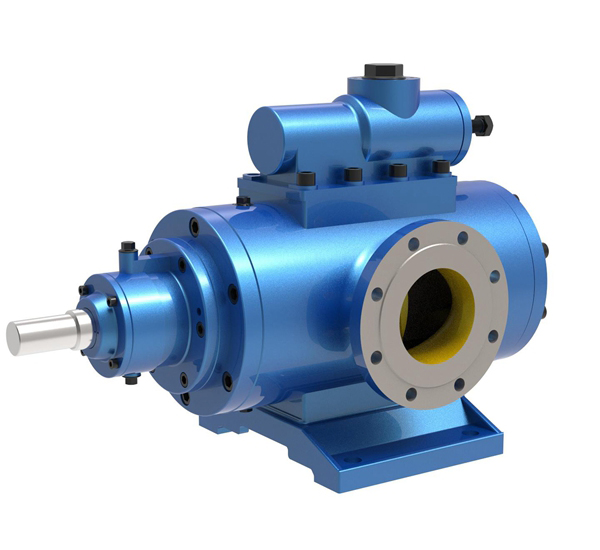

General introduction

Three-screw pump normally consist of a power rotor, two idler rotors and a rotor liner. The power rotor is engaged with idler rotors, and they form sealed chambers with the rotor housing. When the pump is driven by motor or engine, the medium is absorbed and sealed in the sealed chambers that move continuously towards the outlet along the axial direction when the rotors are rotating, and the medium is discharged at the outlet, so that the liquid transferring is achieved.

SN series:Replaceable liner and mechanical shaft seal

GR series:Integrated casing and liner, shaft is lip seal

Key features

1.Good self-priming and high efficiency

2.Horizontal or vertical installation

3.Applicable for lubricating fluid or clean fuel oil

4.Easy maintenance and low noise

5.Pressure relief valve applied as protection

Performance range

- Capacity: 380m3/h

- Pressure: Max.40 bar

- Temperature: 180℃

- Viscosity:1500 cSt

General introduction

Twin-screw pump is kind of rotary displacement pump, several sealed chambers are formed in pump casing due to engagement of power rotor and idler rotor and close fits between the rotors and liner when power rotor is driven. These sealed chambers move forward continuously when the idler rotor is rotated by timing gears, that to push the liquid in the sealed chambers to discharge chamber and discharge line, so that the liquid transferring is achieved.

Multiphase screw pump is applicable for oil,gas and water fluids, GVF is up to 99%, diff.pressure is up to 500 psi.

Key features

1.Low shearing to fluid and stable discharge pressure

2.Not direct contacts between rotors and between the rotating parts and fixed parts

3.Various shaft seals for different operating conditions

4.Heating jacket is available as requirement

5.Replacement liner is available

6.Wide applicable for liquids of low or high viscous, clean or abrasive, neutral or corrosive chemical, also for oil, gas and water multiphase

Performance range

- Capacity: 2000m3/h

- Pressure: up to 70bar

- Temperature:Max.300℃

- Viscosity: Max.1000000 cSt

For catalogue, contact sales@shenmech.com

General introduction

Progressive cavity pump is called P.C pump,also single-screw pump.when the rotor is driven by external force, the rotor makes planetary movement inside the stator, that makes the sealed chambers move to the pump outlet at a uniform speed. The rotor with continuous movement produces a continuous sealed cavity chamber, so that the fluid is continuously suctioned from pump inlet and discharged to the outlet of pump, so this realizes the continuous transmission of the medium.

Generally,single-screw pump market demands are more than twin-screw pump and three-screw pump worldwide.

Key features

1.Wide application from water, waste water to viscous fluid

2.Horizontal or vertical installation

3.Low noise, simple structure and easy maintenance

4.Low shearing force and pulsation

5. The flow rate is proportional to rotation speed

6. Hollow rotor available for higher pump efficiency

7. Equal-wall thickness stator design for higher working pressure with compact structure

Performance range

-Capacity:400m3/h

-Pressure:46bar

-Temperature:-20 to 120 ℃

-Particle OD Max:28mm

For catalogue, contact sales@shenmech.com

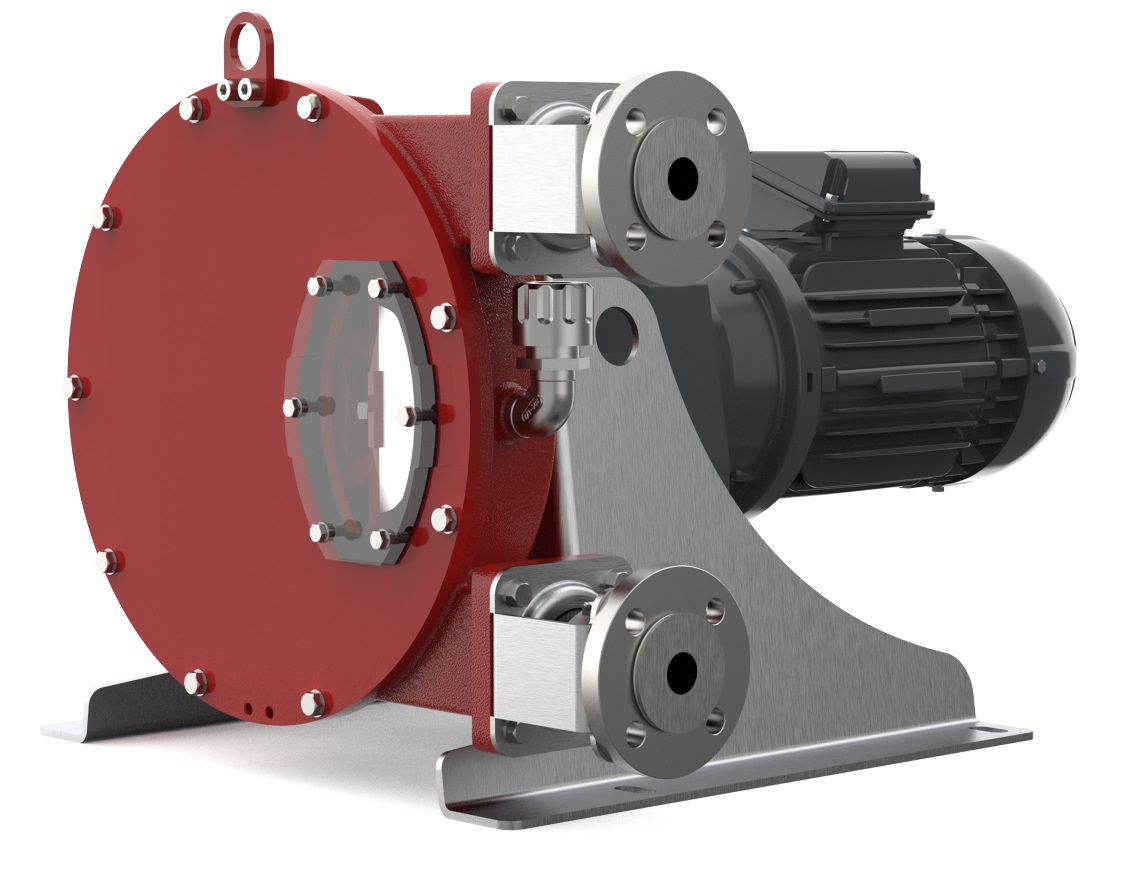

General introduction

The peristaltic hose pump is a kind of positive displacement pump with simple working principle, the pumping purpose is achieved by alternately compressing and relaxing a machined hose between the pump housing and the compressing shoes. The fluid ahead the shoe is pushed towards the discharge while the rebounding hose behind the shoe draws more fluid in. With 100% compression at all times, the pump provides stable metering accuracy and pressure performance. With no pump seals or valves, abrasive or aggressive fluids are safe to be pumped as fluid to contact only the inner wall of the hose.

Key features

1.Suction height is up to 9.1m and very strong self-priming

2.Dry-run definitely is allowed without damage

3.Ideal for shear sensitive or high viscosity fluids

4.Good solution for acids, large solids and abrasive fluids

5.Very easy maintenance – just change the hose

6.Hose material option: NR, NBR, EPDM

Performance range

-Capacity: 96 m3/h

-Pressure: up to 9 bar

For brochure, contact sales@shenmech.com